It's now been seven years since the founder of the World Economic Forum, Klaus Schwab, uttered the phrase “fourth industrial revolution” (4IR) at a conference in Davos. Nonetheless, the hype around its potential, how it would look, and its arrival date has not stopped since.

In his book bearing the same title as the phrase, Schwab describes the 4IR as “a technological revolution that is blurring the lines between the physical, digital, and biological spheres.”

As we become more dependent on technologies such as artificial intelligence and it continues to play a greater role in our lives, many no longer regard the 4IR to be something of the future but insist it’s here now – the next step is building trust in AI to accelerate its adoption. You can learn more about revolutionizing decision-making with AI in our separate webinar.

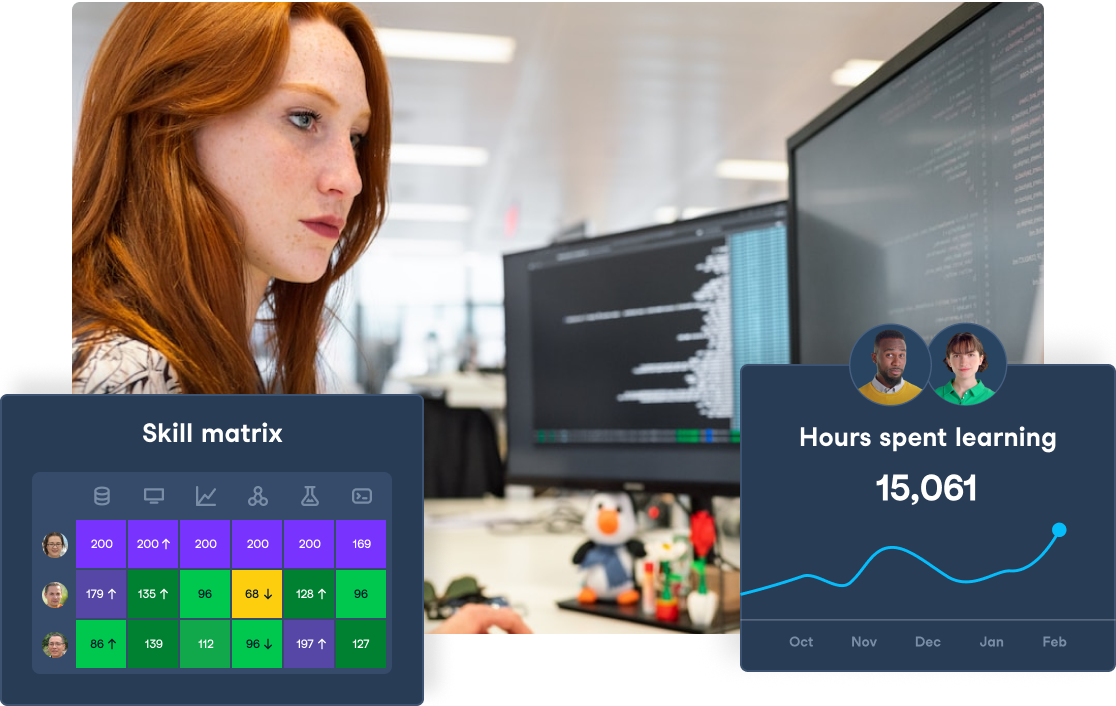

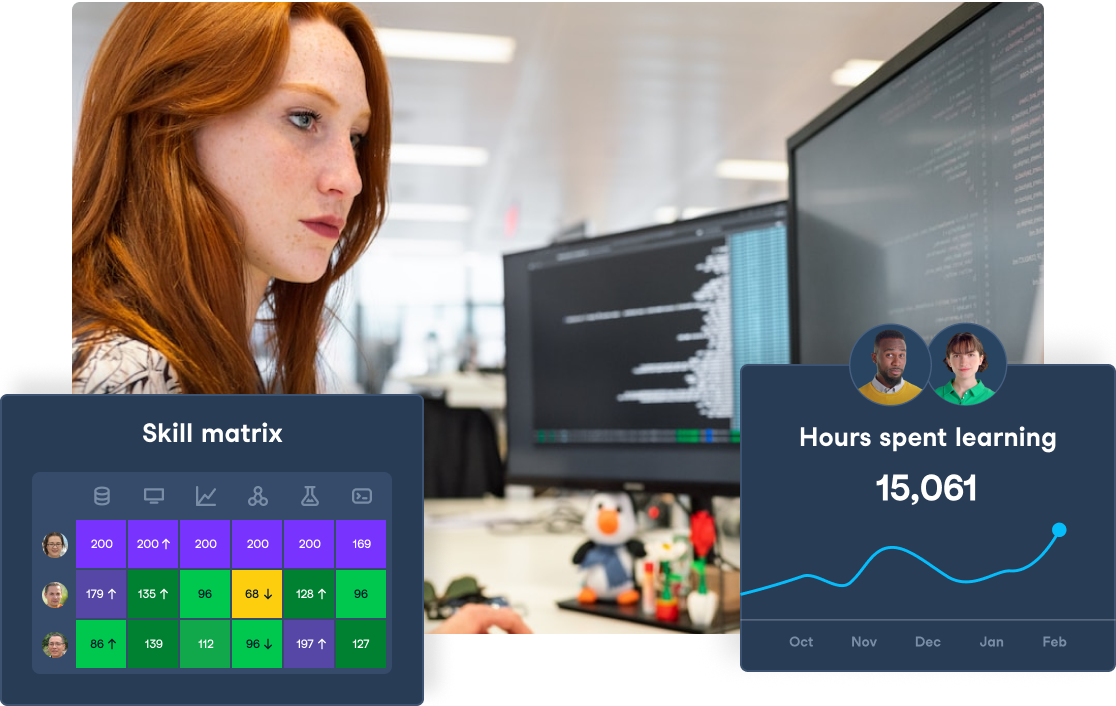

Elevate Your Organization's AI Skills

Transform your business by empowering your teams with advanced AI skills through DataCamp for Business. Achieve better insights and efficiency.

The Emergence of AI in Industry

AI has been one of the biggest buzzwords of the twenty-first century, with the majority of the drive coming from the last decade. Despite the relatively recent push for the advancement of artificial intelligence, its origins date back to the mid-twentieth century.

The Turing Test

In 1950, Alan Turing brought the concept of artificial intelligence to the consciousness of humanity. In line with his thoughts, he developed the Turing test to identify whether machines can think to a similar level of humanity or beyond. Unfortunately, not many breakthroughs occurred heading into the late 60s, which became known as the first “AI winter” due to a lack of funding being pushed towards research and development of AI.

Robots enter manufacturing

However, silently in the background, aspects of AI started to be integrated into manufacturing despite the little growth during this period. For example, an assembly line robotic arm named SCARA was developed in 1978 and was utilized in manufacturing. But It wasn’t until the 1980s that we saw the next boom of AI research and development, and chess had a significant role to play.

Checkmate for AI

Garry Kasparov, the chess world champion of the time, was dominating the game. Chess was recognized as the penultimate game to defeat as overcoming it would mean AI has met Turing’s criteria of building a machine capable of thinking to a person's capacity.

Kasparov wasn’t convinced by the advancement of AI in his domain and went on to proclaim that AI-powered chess engines could not surpass the level of chess grandmasters. This belief was further reinforced when he defeated IBM's Deep Blue in 1996 and its predecessor IBM Deep Thought in 1989, respectively.

But Kasparov ate his words In 1997 when IBM’s deep blue defeated him in a rematch; this moment is said to have ended the second “AI Winter” starting in 1988.

The future of AI

Since then, AI has made steady improvements. However, the next boom wasn’t until 2012, after the deep learning revolution and, more recently, the launch of GPT-4.

Each advancement has played a significant role in the growth of AI, which has gradually poured over into the manufacturing industry. Nowadays, it’s commonplace for manufacturers to leverage AI to optimize production.

AI in Manufacturing Examples

We can define AI as “intelligence—perceiving, synthesizing, and inferring information—demonstrated by machines, as opposed to intelligence displayed by humans or other animals.”

A specific branch of AI known as machine learning has been making groundbreaking advancements in the manufacturing industry due to the significant amounts of data the industry relies upon.

Machine learning enables machines to make decisions without human input based on patterns learned from data. Humans would typically have difficulty sorting through large quantities of data, but this is simple for a machine.

While a factory filled with robot workers may have seemed like a far-fetched fantasy of science fiction, today, it reflects one real-world scenario in which manufacturers leverage AI.

But manufacturers can benefit from AI in several ways; let’s take a look at a few.

Predictive maintenance

All industry equipment has a lifespan. Failure to maintain it promptly can result in significant monetary and time losses. Servicing equipment too early can also spell time and monetary loss, so the challenge is to identify the ideal time to service or replace equipment. AI-based predictive maintenance has increasingly been introduced to need this need.

Quality control and inspection

Manufactured products often maintain a certain level of quality control to ensure products are of a good standard before they are pushed into the hands of consumers. Enforcing quality control traditionally meant humans carrying out visual inspections to search for defects. The issue with human visual inspections is twofold: 1) humans are typically prone to error, and 2) inspections can take a long time.

Passing on the responsibility of visual inspection tools to AI-powered inspection equipment, such as machine vision cameras, often results in faster and more accurate defect detection and inspections, so companies can feel more confident their products meet the desired quality before they end up in the hands of consumers.

Process optimization and automation

Technologies such as Robotic process automation (RPA) simplify the requirements to build, deploy, and manage software robots that mimic human actions interacting with digital systems and software.

Such software can handle repetitive, high-volume processes with better accuracy than humans. Example use cases of RPA include data transfer between systems, searches, calculations, and record maintenance.

Supply chain management

A good example of AI in manufacturing can be seen in supply chain management. Manufacturers typically must process millions of orders, purchases, materials, ingredients, etc. Manually handling these processes significantly affects people's time and resources, hence why more companies are leaning towards AI to augment their supply chain processes.

Cobots

Collaborative robots, or Cobots for short, have been taking on greater supportive responsibility alongside humans instead of in place of them.

Unlike automated robots that are programmed to perform a single task repetitively, Cobots can learn how to perform various tasks and are more often deployed to carry out tasks that involve heavy lifting (e.g., lifting heavy car parts) or working on factory assembly lines. Another use case for Cobots includes locating and retrieving items in large warehouses.

Ethical Implications of AI in Manufacturing

Amid all of the positive outcomes and potential breakthroughs, we may experience as a result of AI in manufacturing, some ethical implications have raised concerns among some groups.

Here are some of the concerns they raise.

Unemployment and increased inequality

The most obvious concern is the threat to the security of humanity. To some, this threat is existential, but to others, it’s more about the demand for labor.

Traditionally, technological progress results in an increased demand for highly skilled labor, while the demand for workers with less education and fewer skills decreases.

However, as IBM’s chairman and chief executive, Arvind Krishna, predicted at Davos in January 2023, we could see the opposite with the AI revolution:

“You should worry more about the clerical, white-collar jobs than the physical [jobs]. A large number of them will get replaced. So the question is: ‘What jobs do you create to replace those?’”

Arvind Krishna, Chairman and Chief Executive IMB

As machines become more intelligent, they are set to replace many humans in the workplace, leaving many who lack the skills of the 4IR out of work.

Cybersecurity Threats

Cybercriminals are constantly coming up with new ways to hack into systems, raising many concerns about AI since they are more vulnerable to cyberattacks. The World Economic Forum highlights the manufacturing sector’s main threats to be:

- Phishing attacks

- Ransomware

- Intellection property theft

- Supply chain attacks

- Internet of Things (IoT) attacks

As humans, products, and equipment become more connected via the IoT, even a small breach in the system is enough to disrupt an entire production line and, in worst-case scenarios, completely shut down a manufacturing business.

Bias

One of the tradeoffs made when trusting AI to process logs of data rapidly is the potential it may learn inherent biases. AI cannot always be trusted to be fair and neutral.

For example, an AI system trained to predict future criminals showed a strong bias toward black people. The people building the systems also have to be factored in. It is humans who create these AI systems, and people tend to have their own biases, which they may insert.

When it comes to manufacturing, AI bias could cause several problems.

In predictive maintenance, for example, AI models trained on biased datasets might fail to accurately predict equipment failures, leading to unexpected downtimes, increased costs, and lowered productivity.

Bias can also skew automated quality control processes, potentially favoring certain products or parts over others based on flawed data.

Furthermore, in AI-driven supply chain management, biases can result in unfair vendor selection, inefficient allocation of resources, and misjudged market demand. These impacts could not only affect operational efficiency but also pose reputational risks and create regulatory compliance issues.

Wrap up

Undoubtedly, AI is a revolutionary technology; a growing number of businesses are already adopting it to improve practices, make better decisions, and build better products.

As these systems become smarter, manufacturing practices will likely be improved in the process; therefore, companies with a solid grasp of AI fundamentals are likely to hold a significant edge over their competition.

Request a demo of how DataCamp can guide you through the process of upskilling your entire team and building a data-positive culture.

Training 2 or more people? Check out our Business solutions

Get your team access to the full DataCamp library, with centralized reporting, assignments, projects and more